CNC milling

Learning to CNC mill was an excellent skill because it is able to make a wide variety of very strong parts. My puzzle box and my game both use CNC.

CNC milling works by using a computer to push a fast spinning mill bit (like a drill bit) into wood, plastic or metal to carve out the desired shape. This article gives more detail.

The basic steps are:

- Make a model

- Chose tools

- Create a cam path

- Generate G-code

- Set up the stock in the mill

- Mill and hope

I learnt a lot about tool types, feeds and speeds, modeling in fusion 360, designing tool paths, G-code and CNC operation.

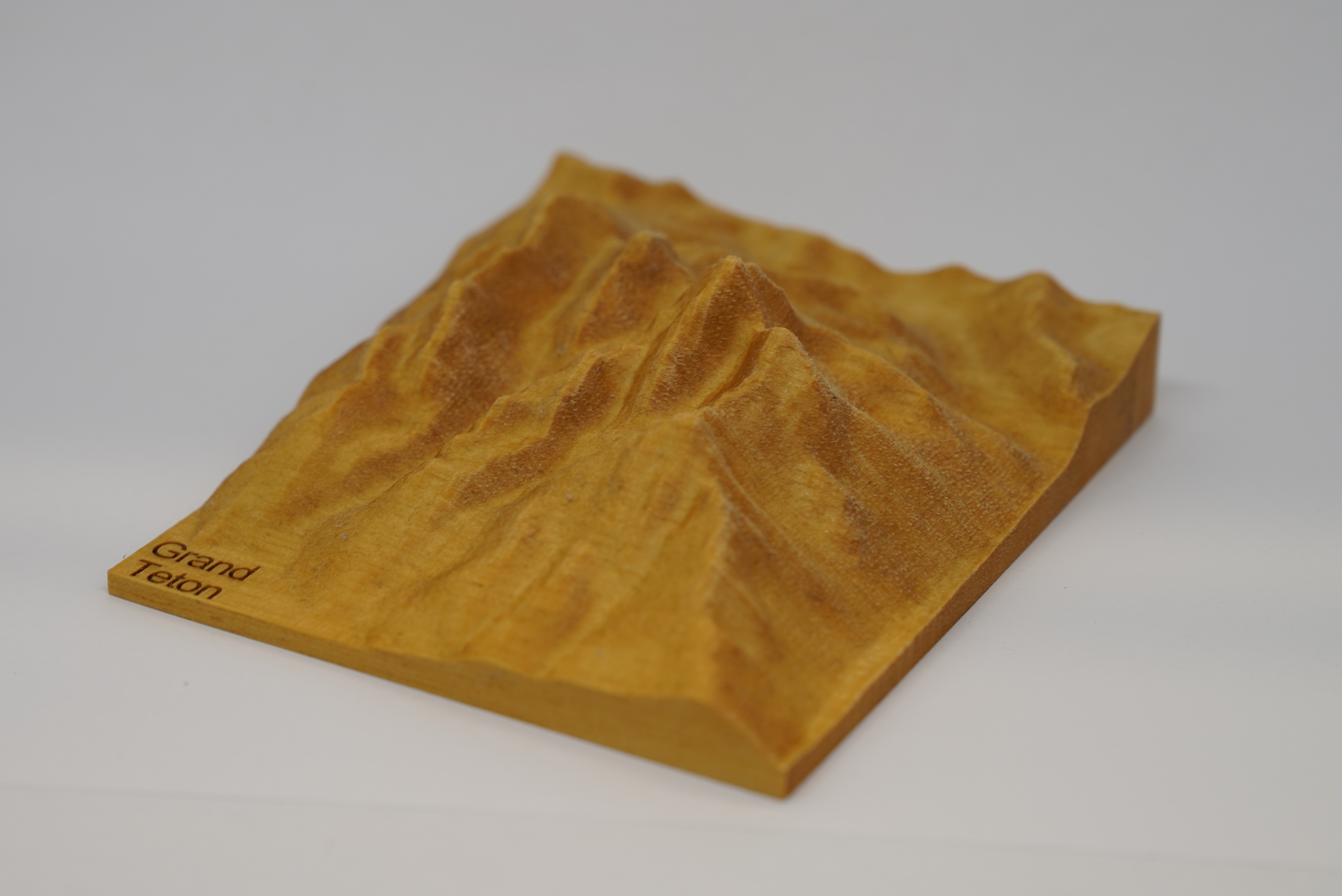

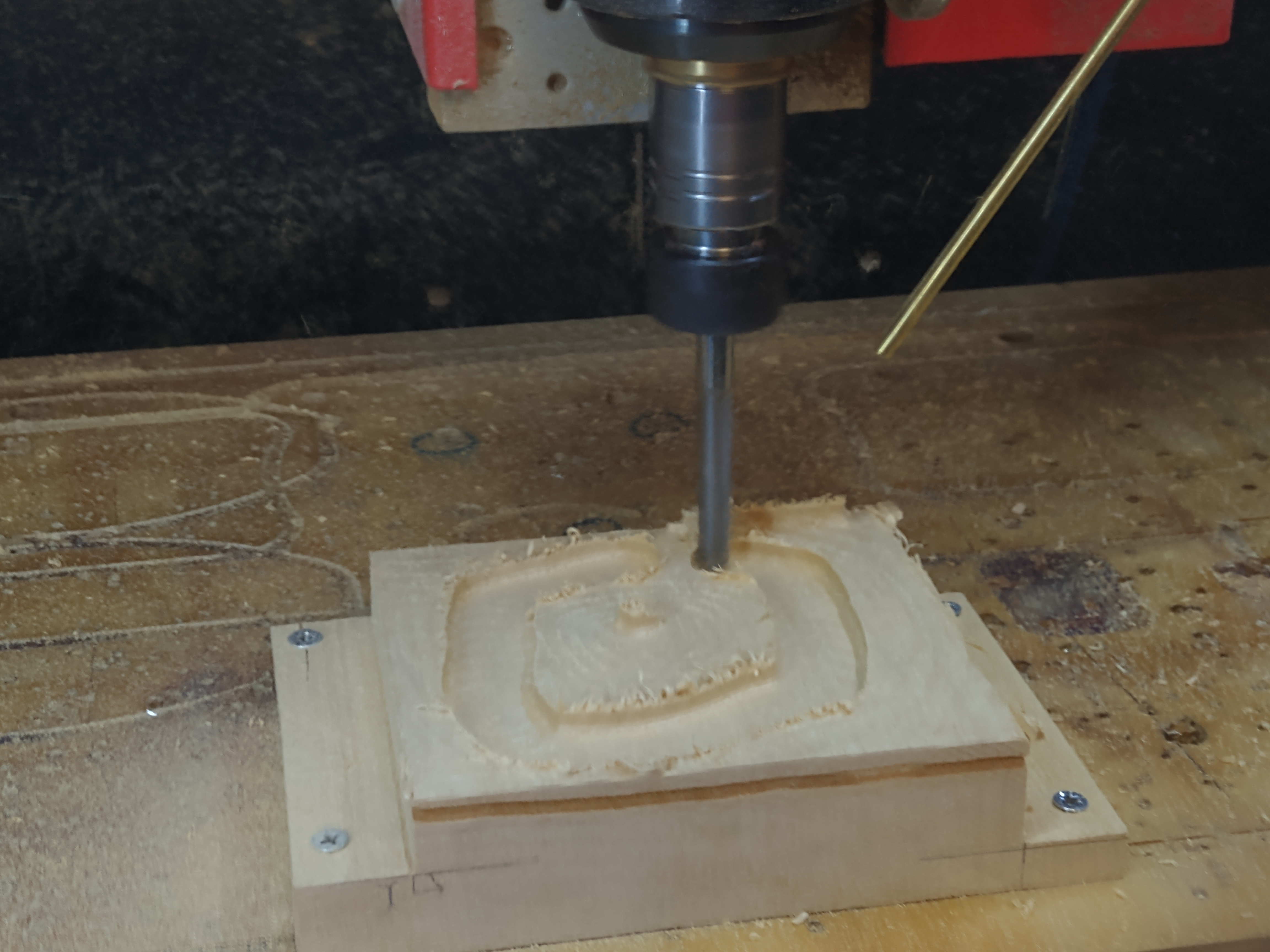

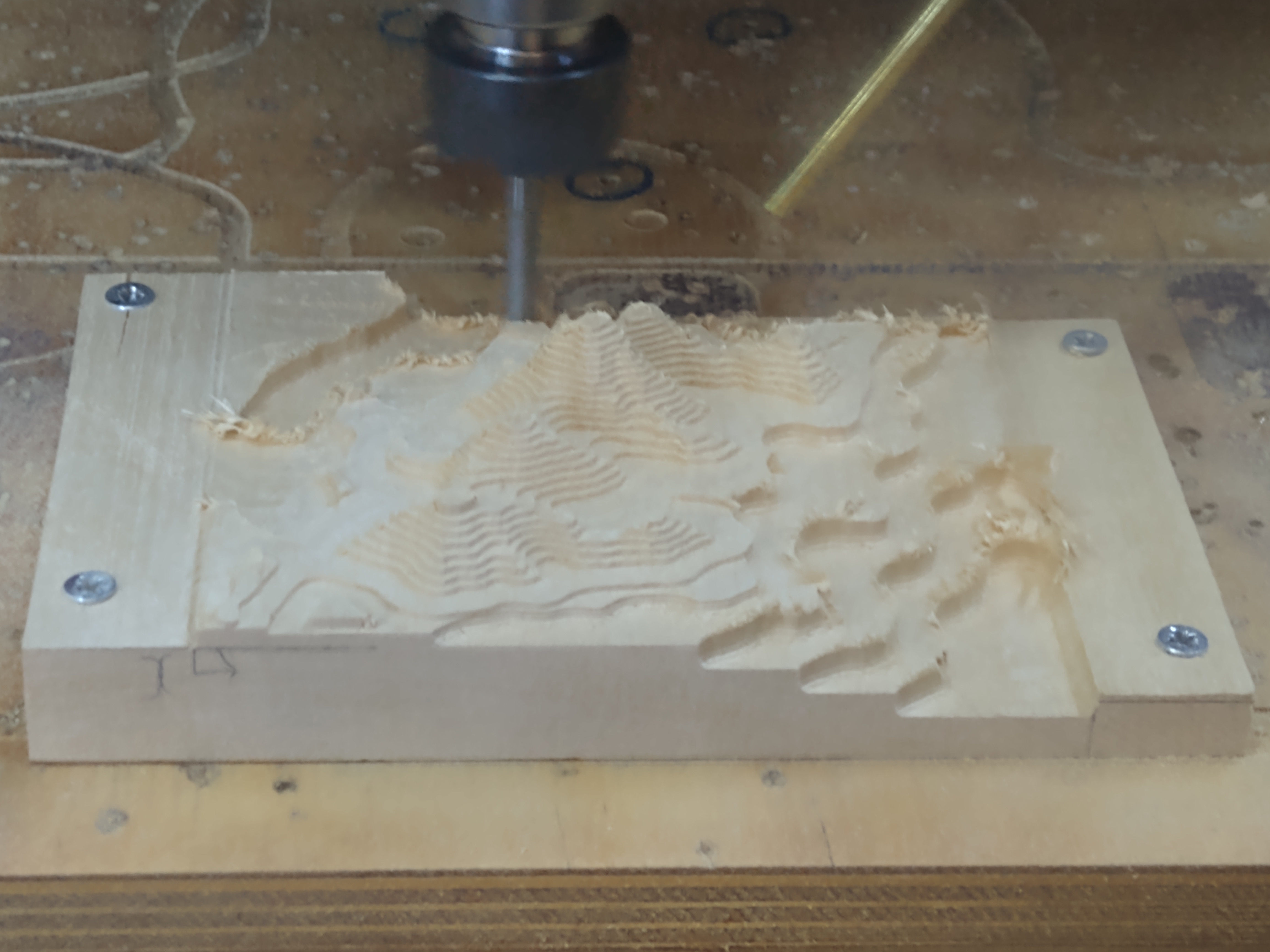

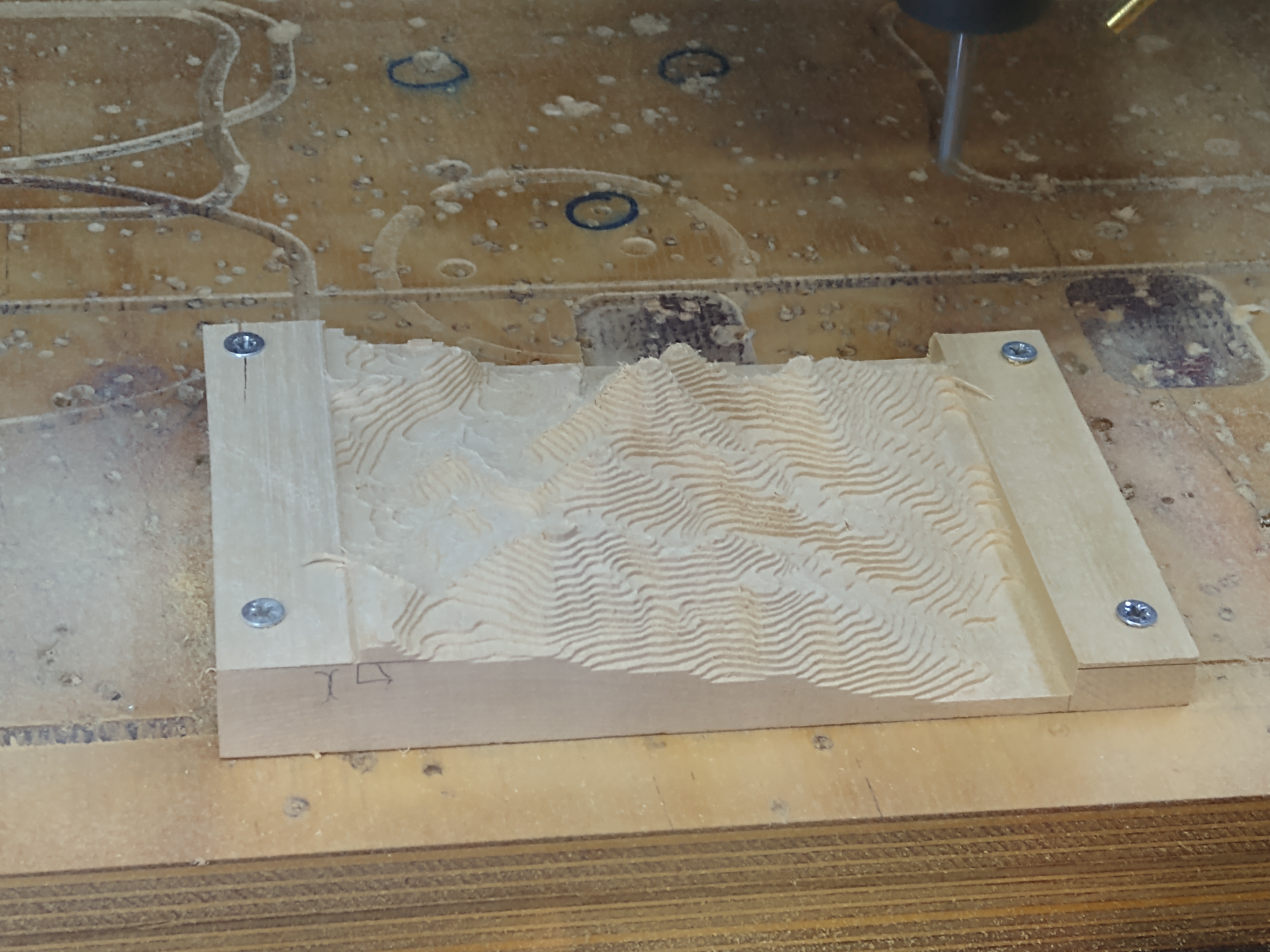

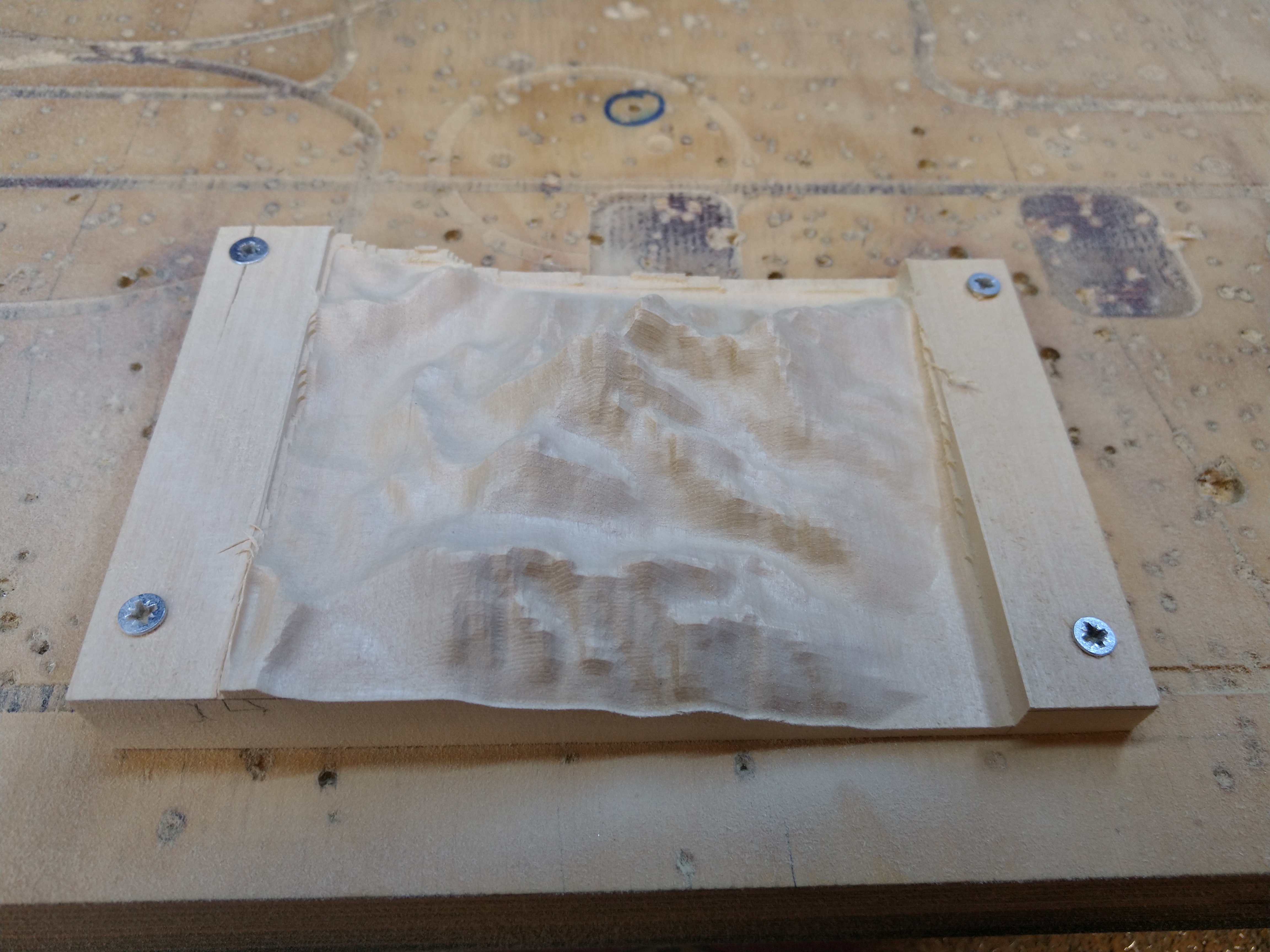

Grand Teton

The Grand Teton is a mountain in Wyoming that my dad climbed and I decided to make him a mini topographical map of it because I wanted to try topographical CNC. I downloaded a STL file of the mountain from an online terrain STL generator. I started with a big 8mm end mill for aggressive clearing and then did finer stepdowns with a smaller 6mm end mill and finishing parallel passes with a small 3mm ball mill. Afterwards I laser engraved "Grand Teton" into the wood and oiled it for protection.

Marble run

This was my first CNC project, so I chose a simple shallow to mill in order to learn how.

To make the actual shape I created a parametrically defined curve and used my python program to turn it into a DXF curve. Then I used rhino to put a pipe around the curve and cut the solid shape created out of a cylindrical object.

Wave

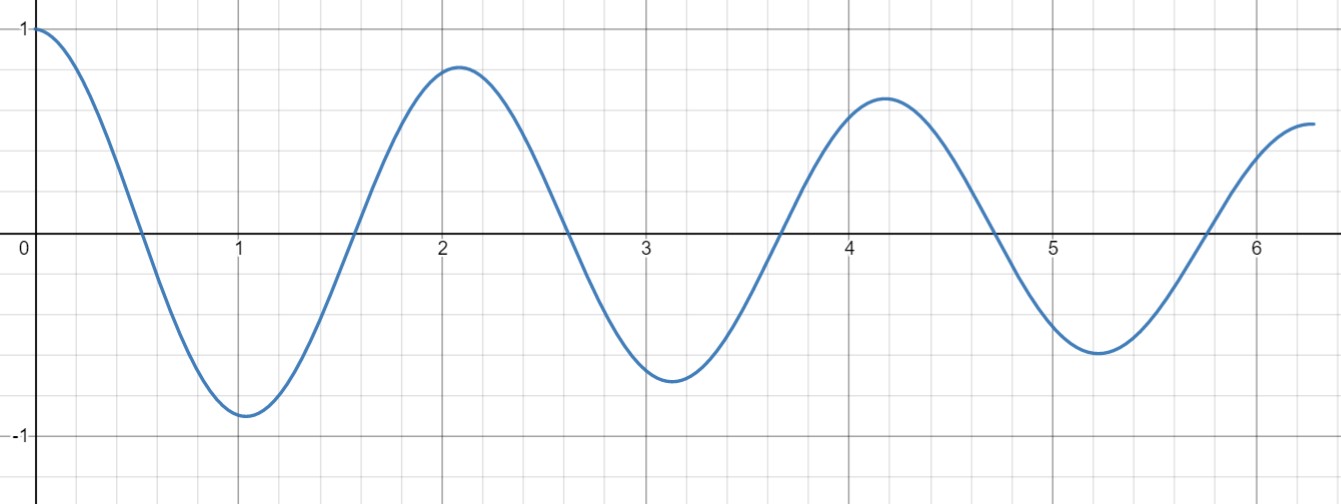

This is water ripple frozen into wood. I used my python DXF program to convert a wave equation to DXF file. I modelled my wave as a cosine wave with an exponential decay: \(y = ae^{-bx}\cos{cx}\)

Then in Rhino I revolved that curve to make the wave surface.

I also made a surface defined by equation: $$z = xye^{-(x^2+y^2)}$$ To model this surface I wrote a python program to create a DXF file with a large grid of points at set x y positions and a z height determined by the surface equation. Then in rhino I was able to fit a surface through the point grid.

I used both of these models to make a cam path in Fusion 360 to cut them out of the wood. You can view the cam path with the top left button shaped like a mill: