Puzzle Box

Simple to solve

Hard to make

My puzzle box has 8 pieces that fit together smoothly with a variety of strange joints I designed. I designed in on the computer then milled it out of a plank of pine and lasered designs on the sides. It took me about 6 weeks of learning to make.

Designing

I designed the puzzle box joint by joint and then assembled the joints onto the pieces. There were a lot of considerations I had to manage:

- Each piece can only milled from one direction

- All internal corners have a minimum radius

- I have to create the pieces to be milled with the available bits

- The maximum milling height is about 50mm

- The faces of all had to be offset by 0.2mm to allow for a good tolerance friction fit

In order to make joints in all directions I had to glue small parts into the main pieces. To determine the offset required for the a good friction fit I had to make a test piece, with offsets of 0.05, 0.1, 0.15 and 0.2mm on different sides.

Milling

I designed the milling path on Fusion 360 in several stages:

- Facing stock above the parts

- Clearing smaller details

- Milling some vertical curves

- Contouring the pieces top outlines with a down-cutter

- Contouring the rest of the depth with an up-cutter

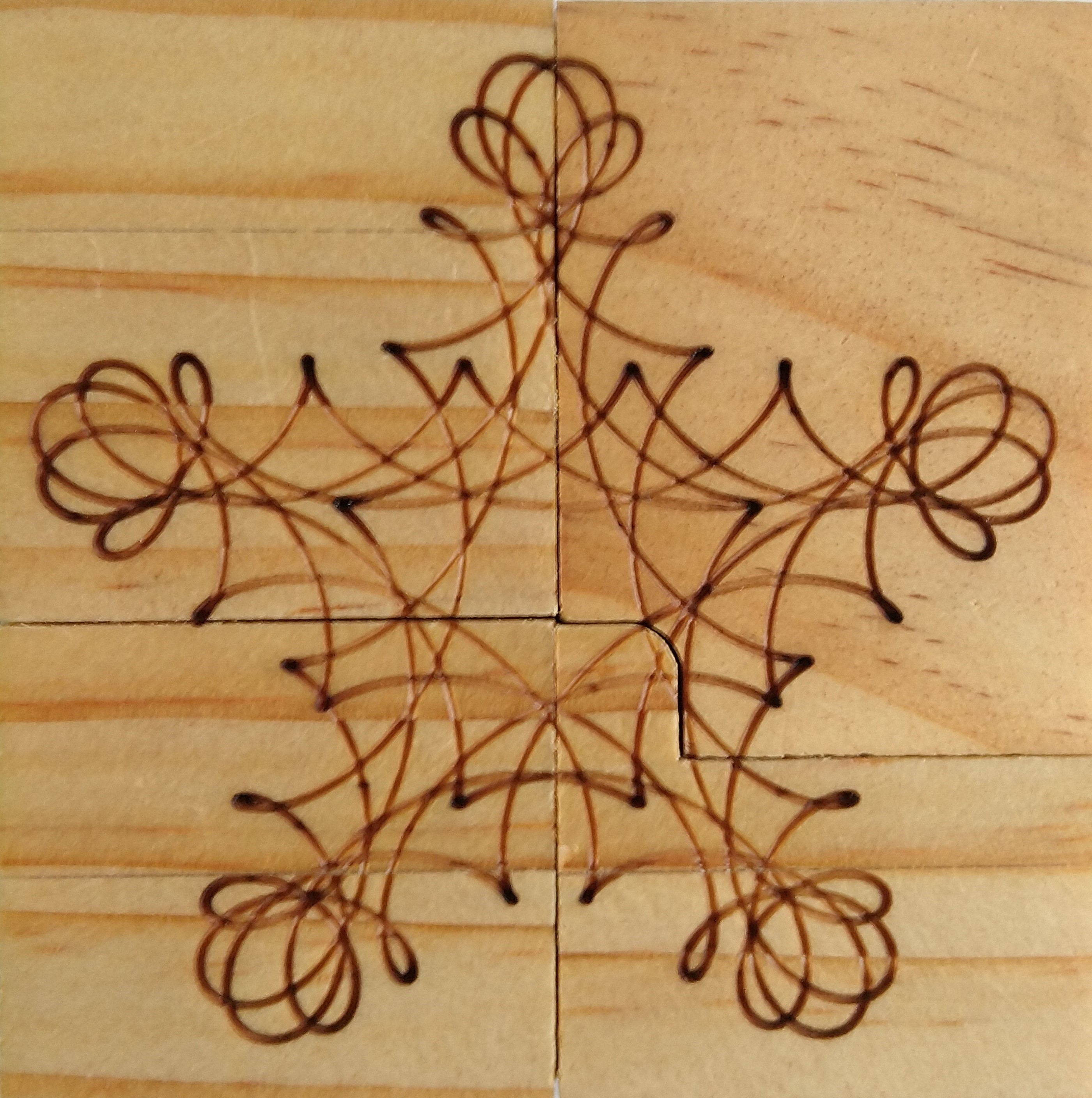

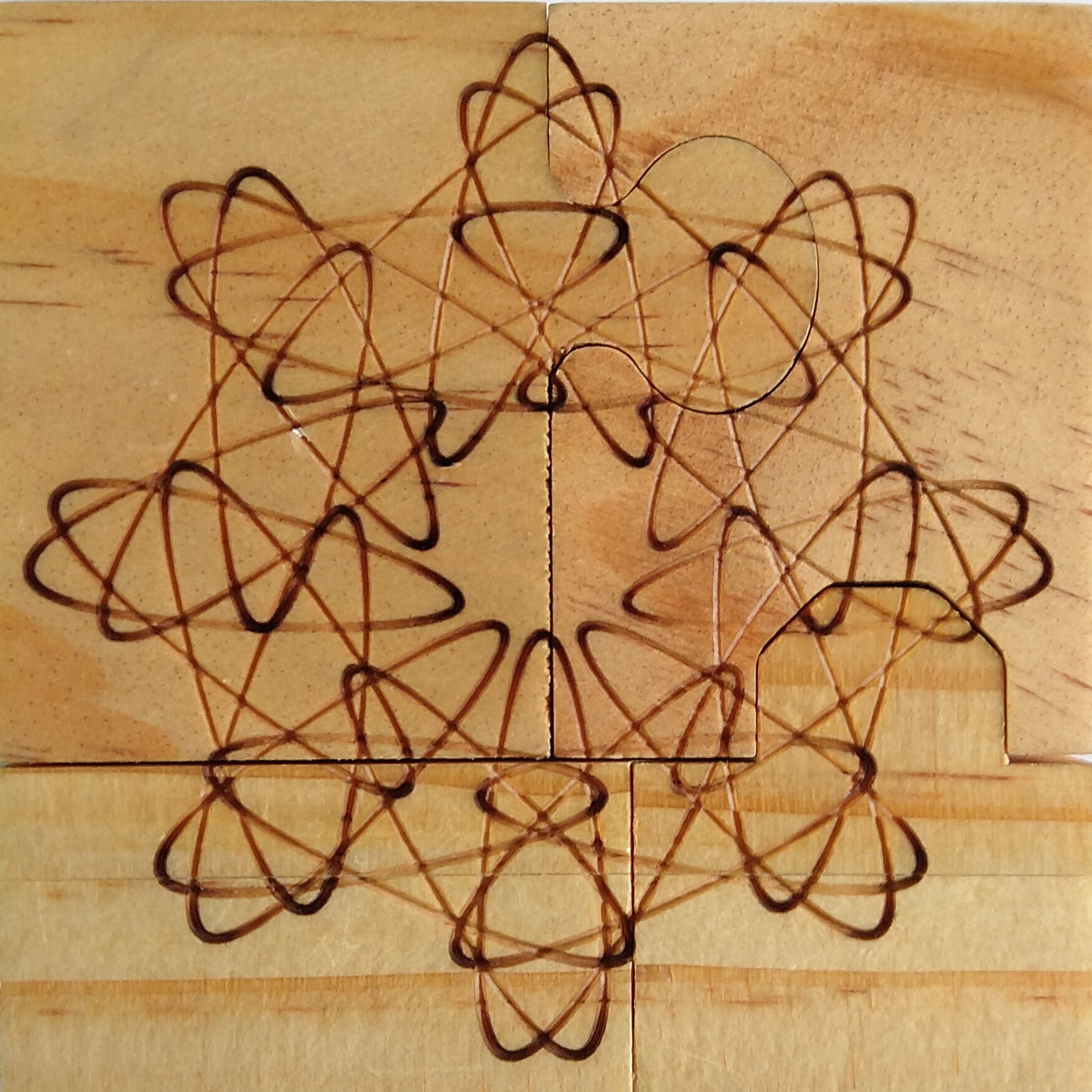

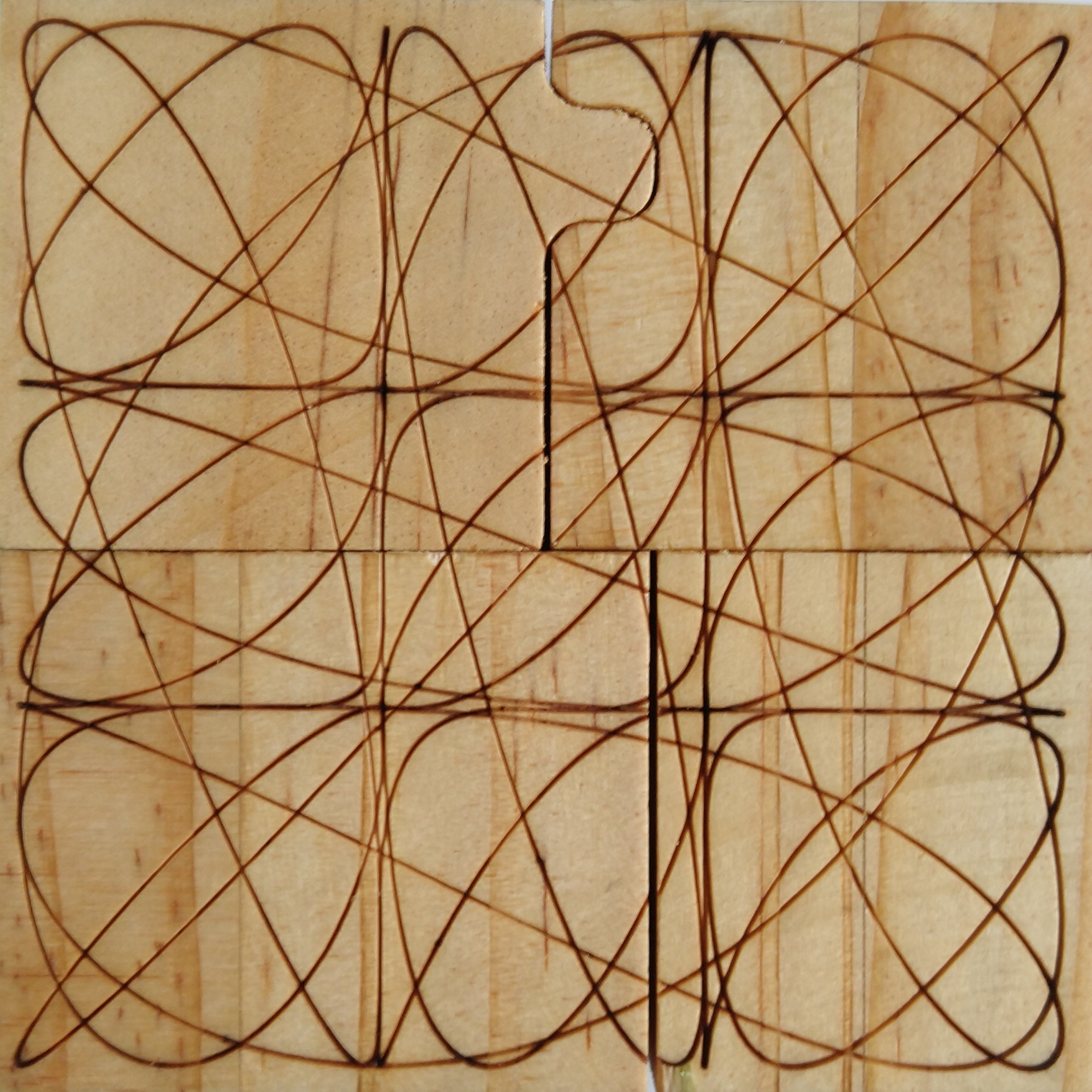

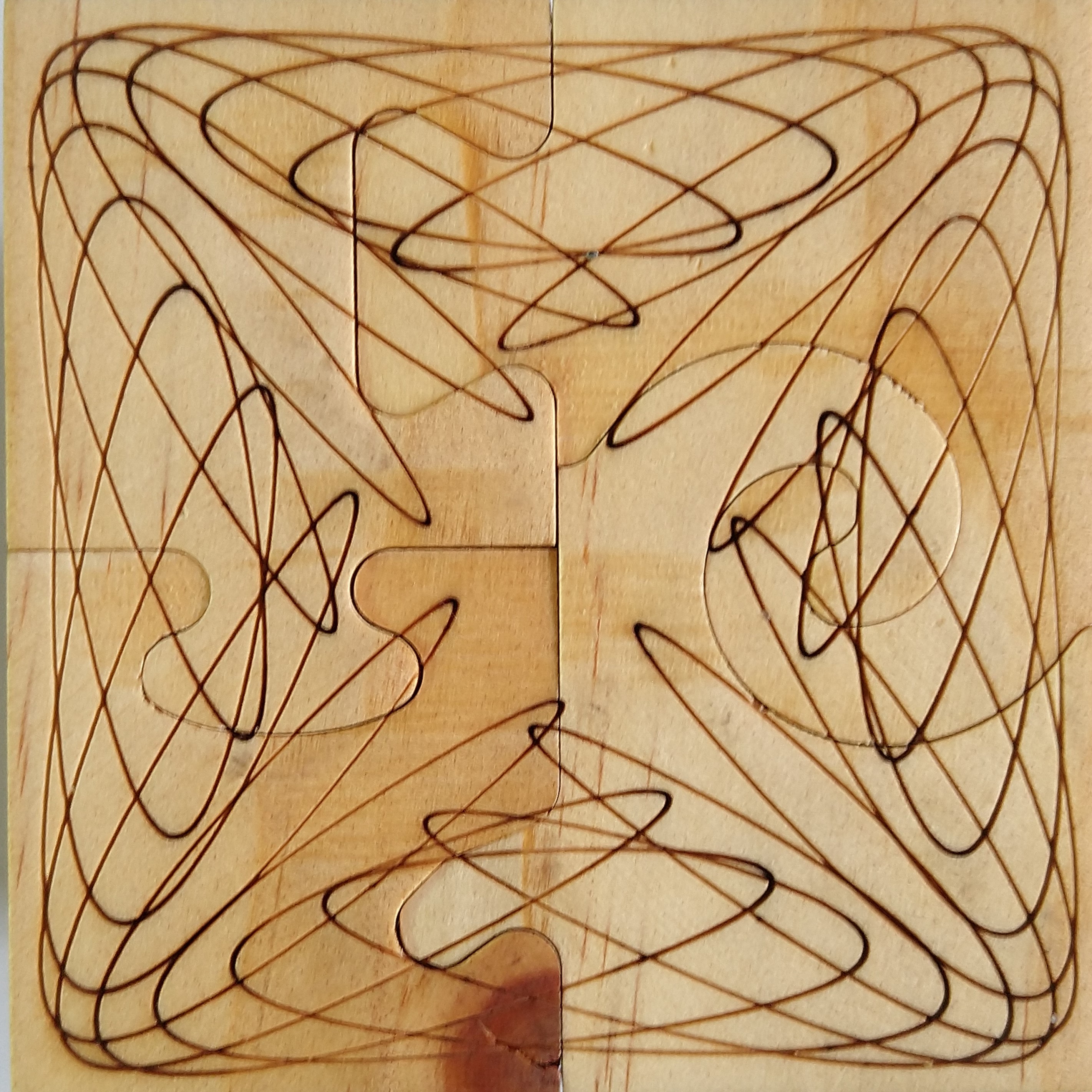

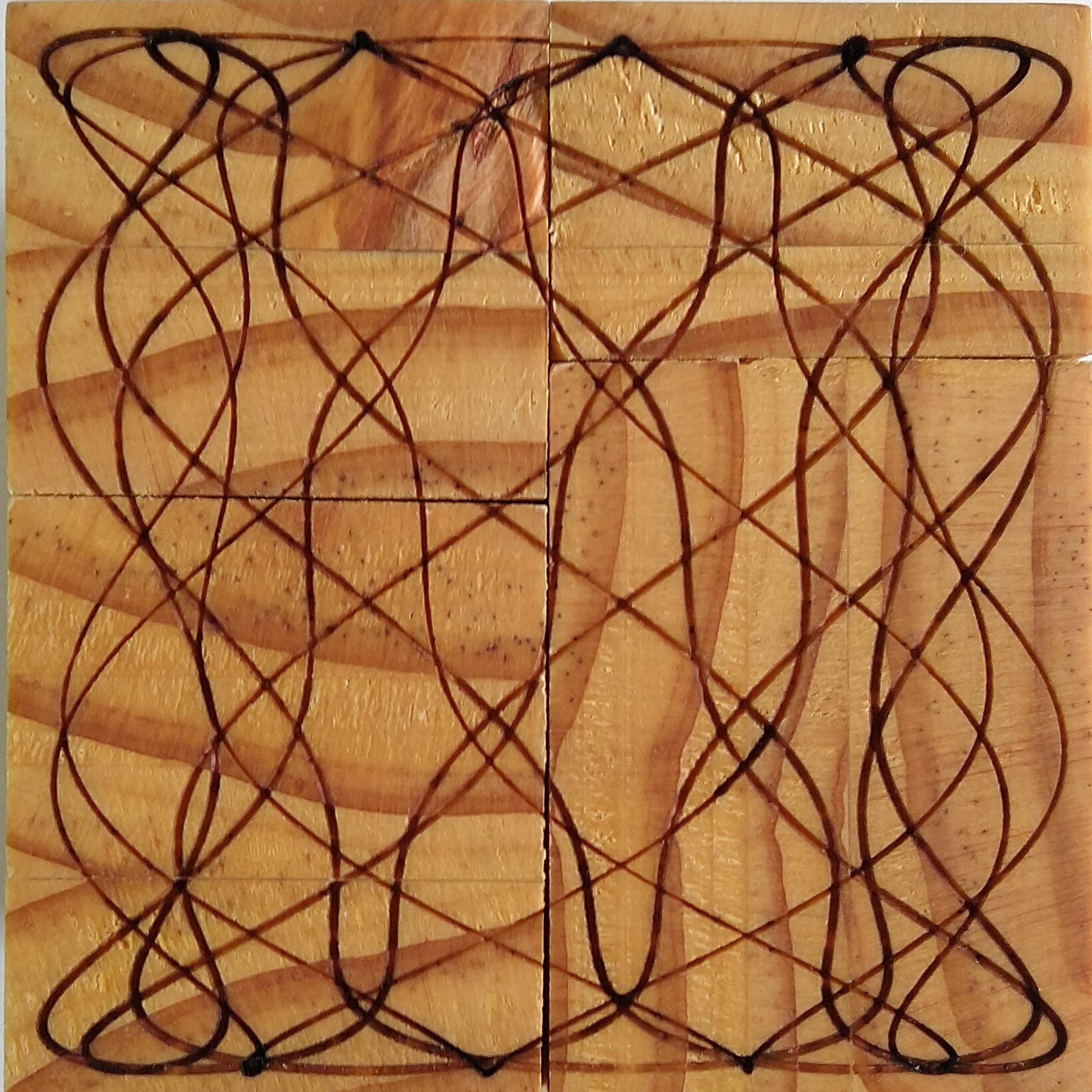

Once the parts had been milled I ran the bandsaw along the bottom to separate the pieces from the remaining stock. Then I glued, sanded, laser scored and oiled the cube to make the final product. I used 6 parametric designs to create the laser patterns on the sides: