Laser Cutting

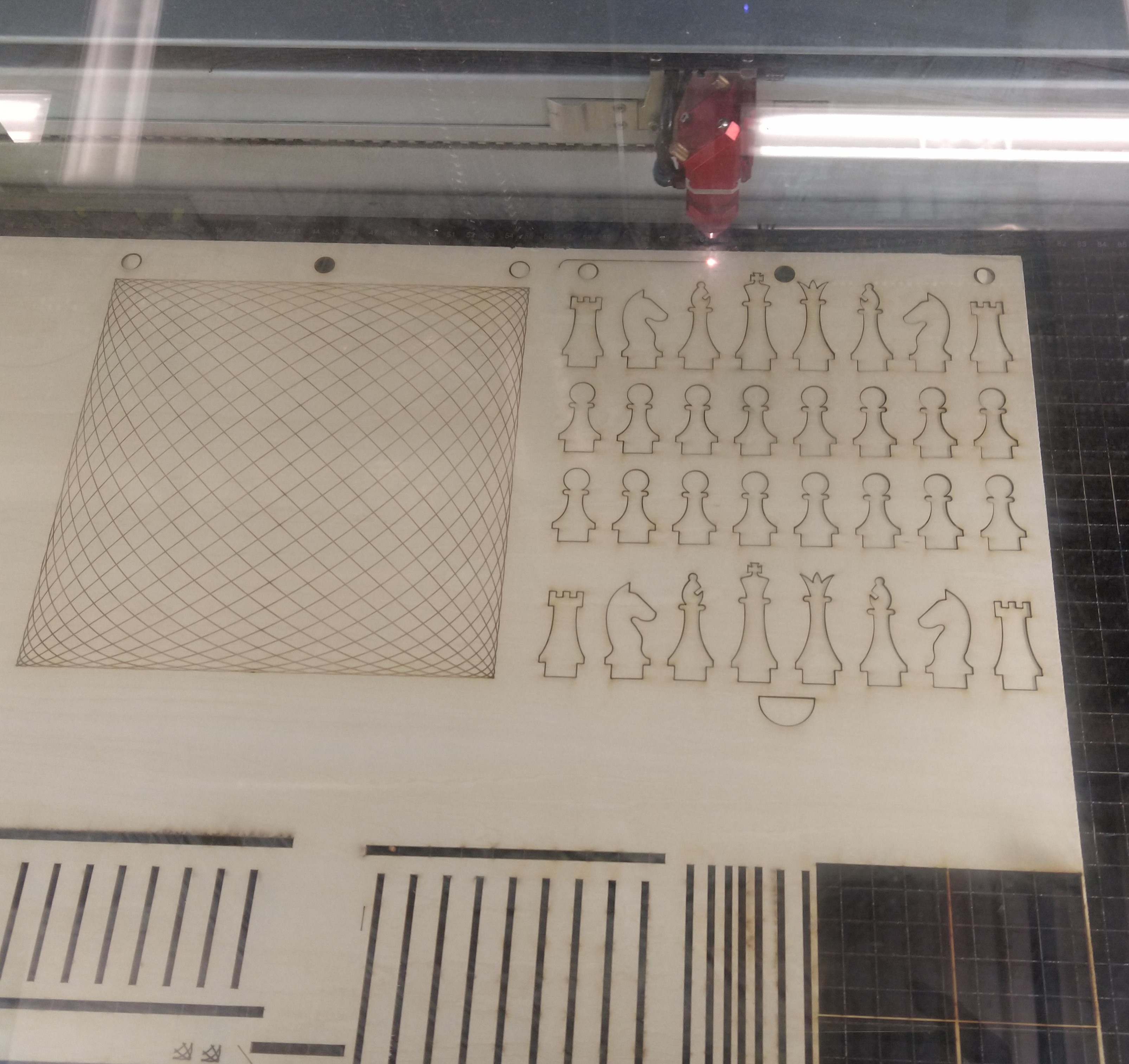

Laser cutting is a very quick method to make 2D parts out of wood or acrylic. I have used it to create artistic pieces and functional parts. I use laser cutting in most of projects because it is so quick and useful. My other projects that use laser cutting are my clock, chess boards, game, puzzle box, parametric designs and robot.

Laser art

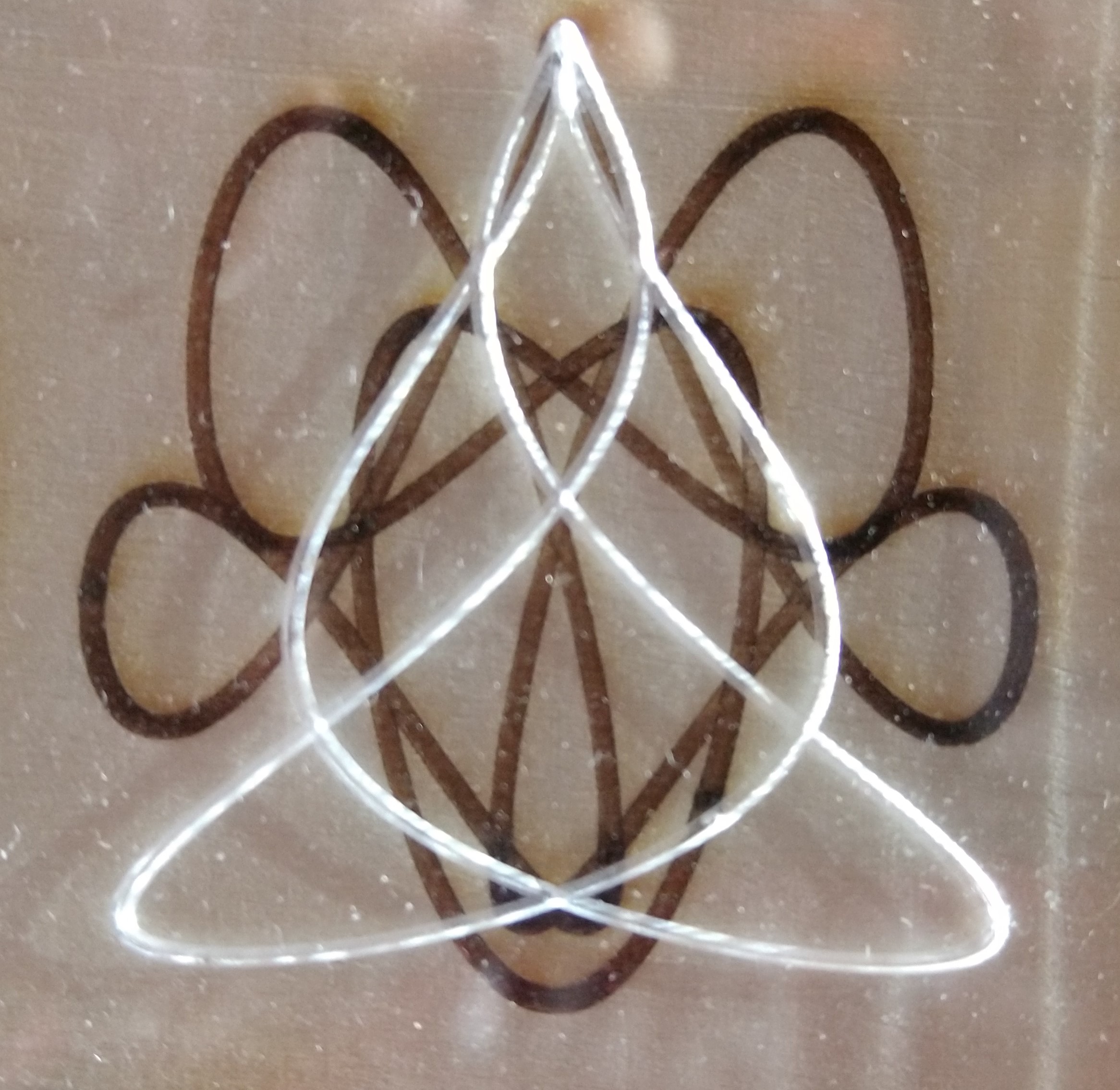

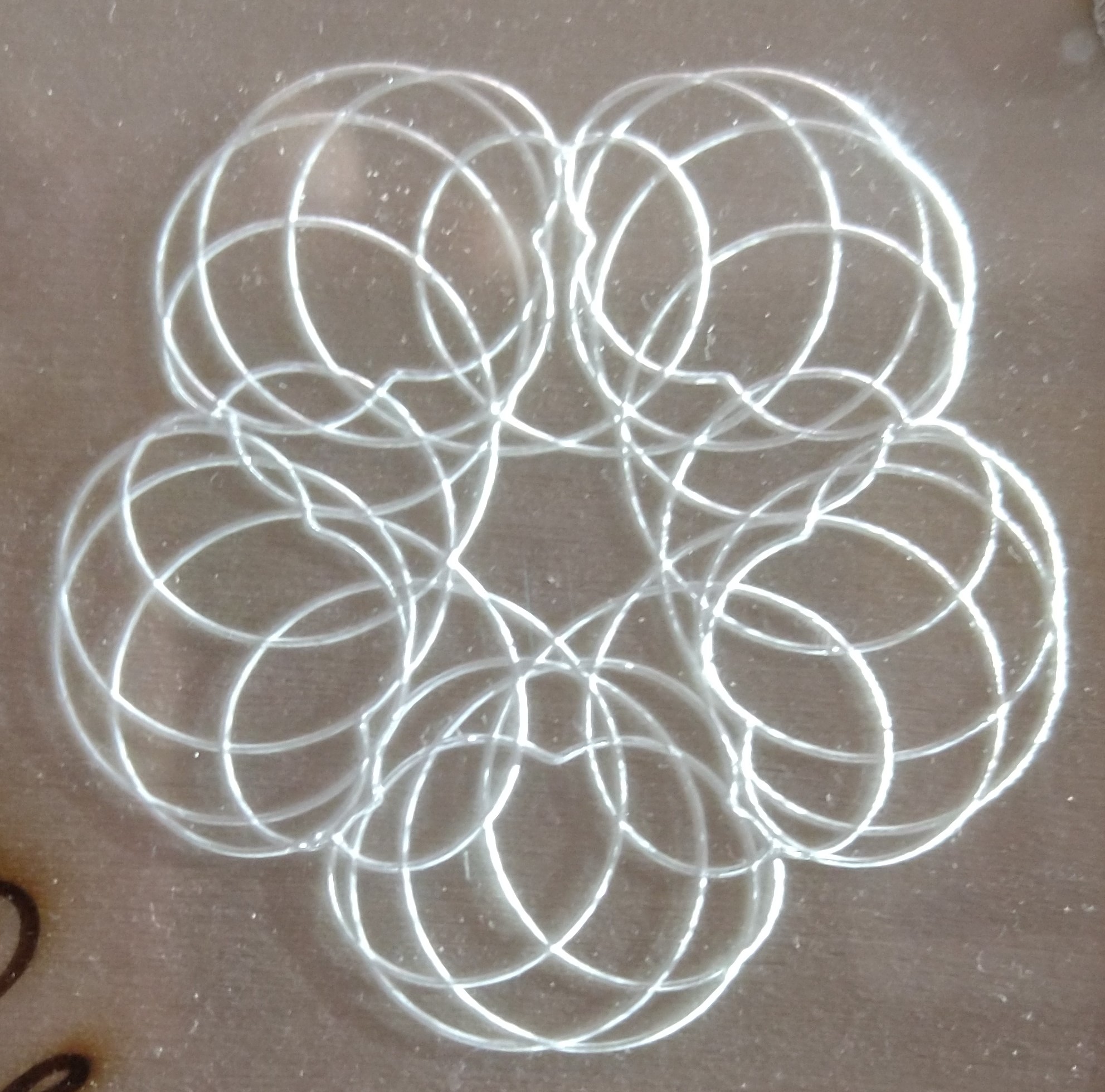

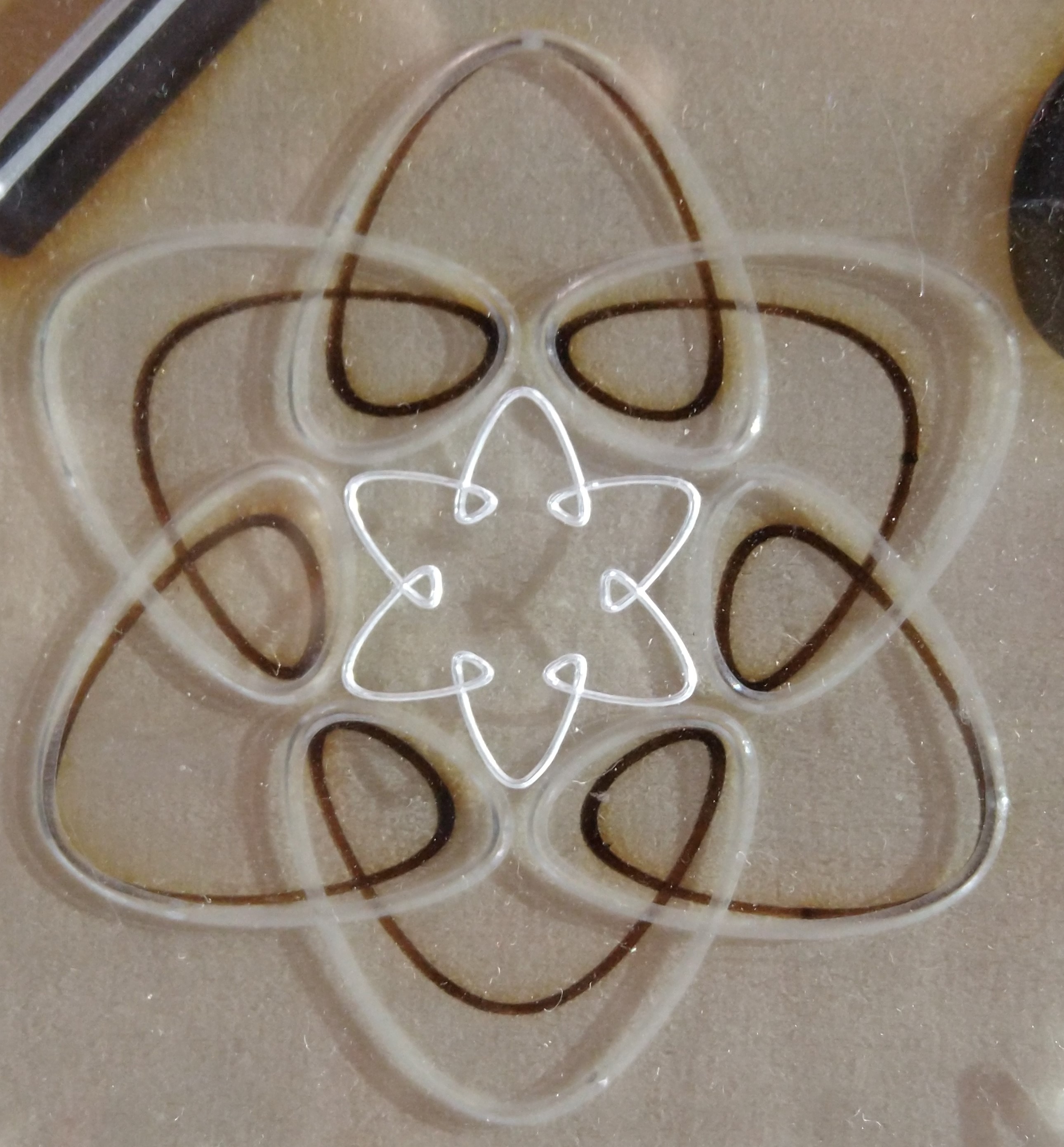

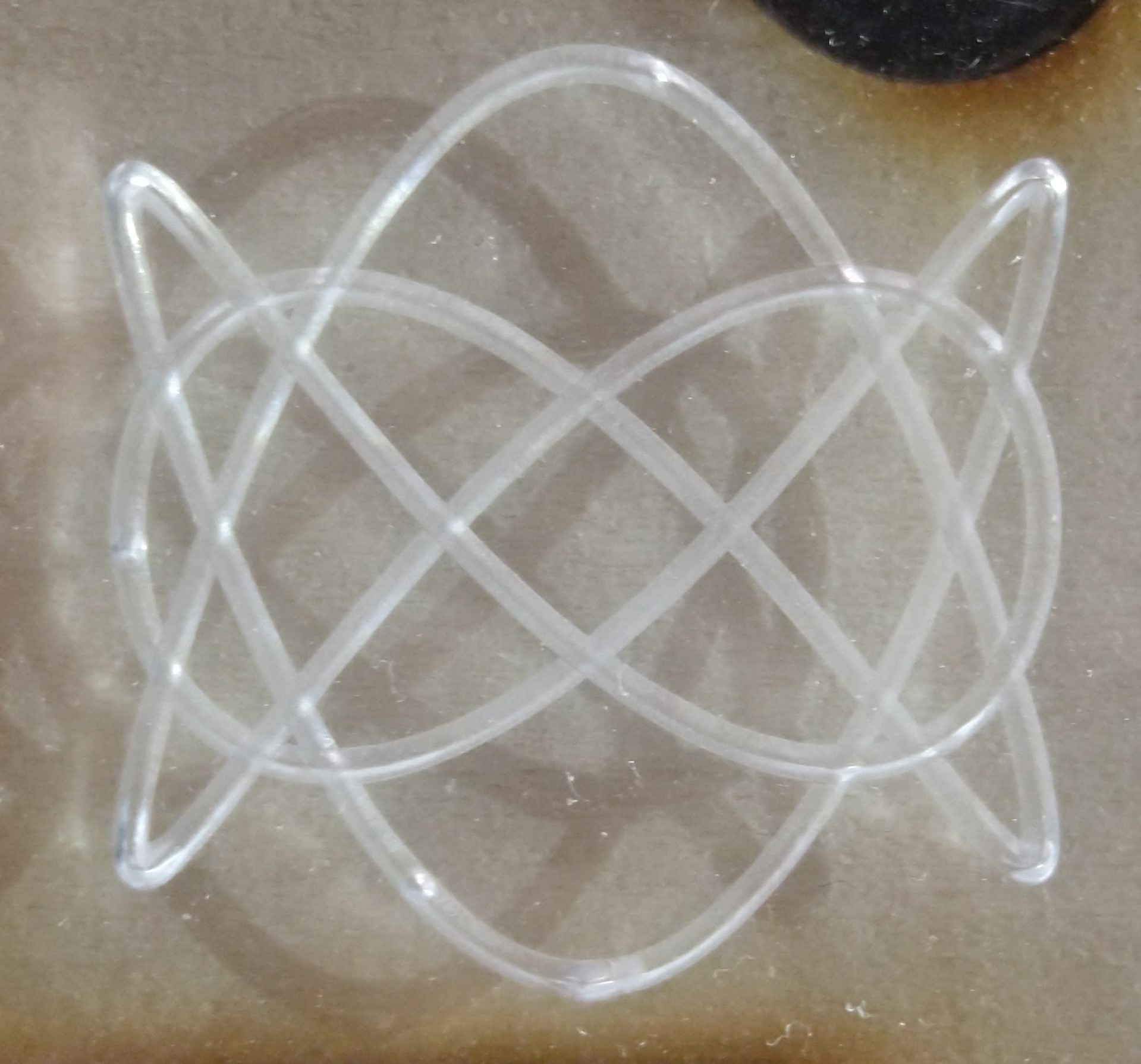

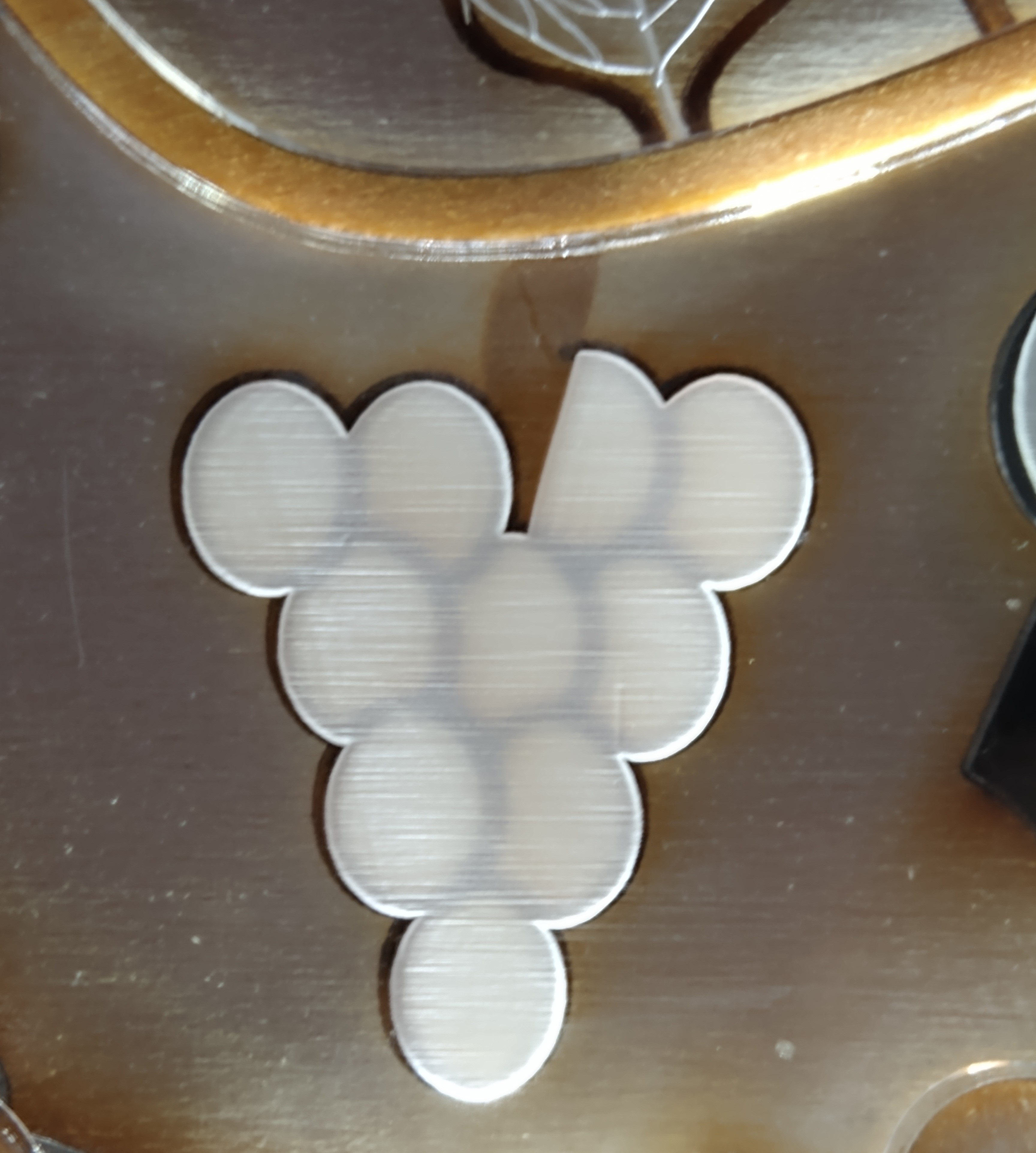

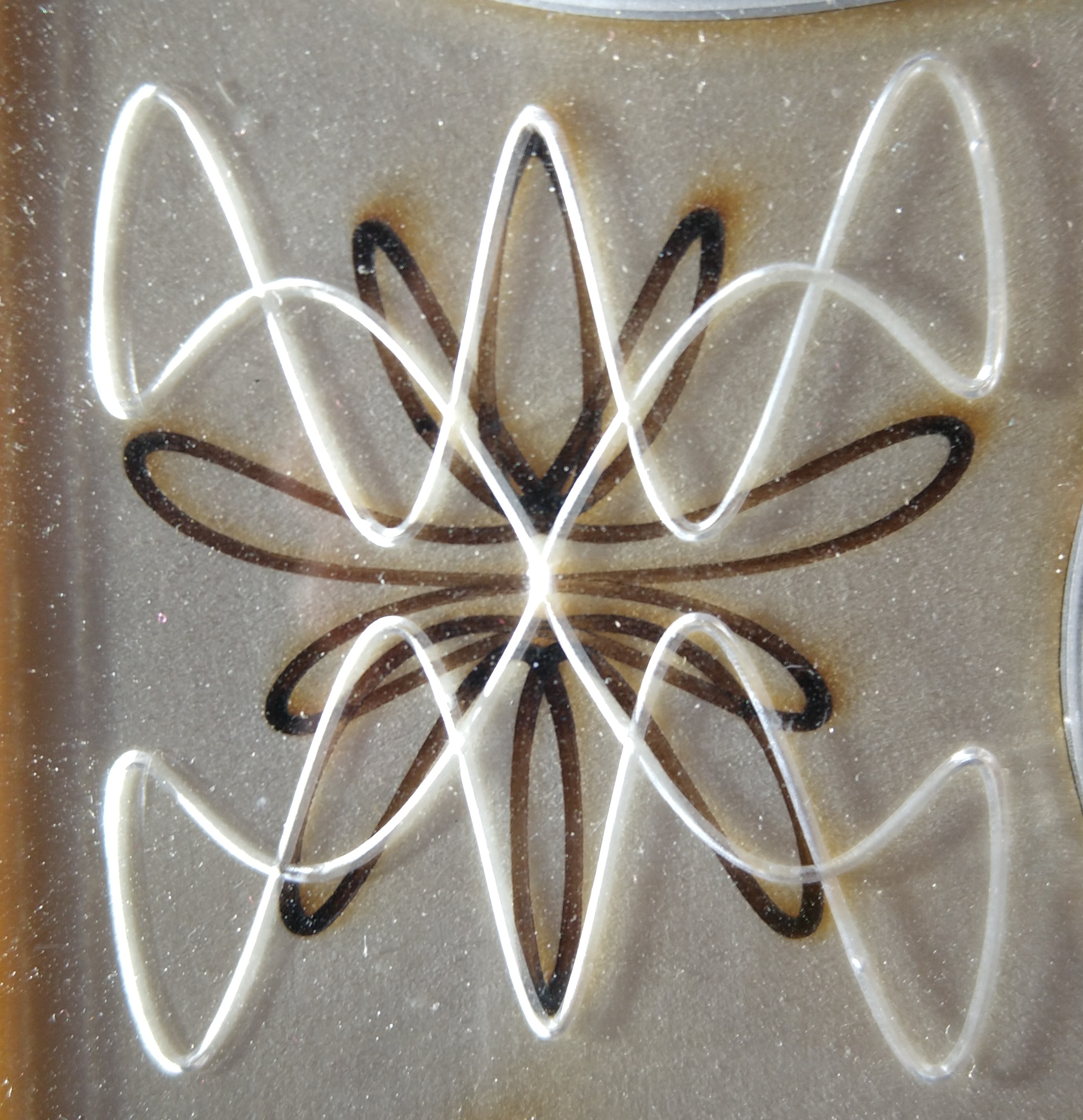

This is my biggest laser cutting project, combining everything I have learnt. The piece is made with three layers: two of acrylic with wood inlay and one of wood with acrylic inlay. Each of the layers also has uses many different techniques to make all sorts of effects. There are many parametric curves scored onto the acrylic and wood and these were all created with my parametric python program. There are also various geometric shapes which I designed in Rhino, and I could get quite creative with the effects because I could make shapes overlap but be on different layers to create 3D effects. Laser engraving on clear acrylic makes it turn frosted, so I engraved circles on three layers of acrylic to get an effect like bubbles. The acrylic also lights up when light is shone from the side, which looks epic. In the middle I created a river with wooden inlay swirls. I also designed a grapevine at the top, with intricate leaf patters and a mini bunch of grapes.

I designed my own laser settings to make this because I wanted complete control over the result. The laser works by taking in a file of colored lines and then cutting each of this lines with the power specified. It doesn't know what it is cutting so you need to choose the appropriate settings of speed and power. By deliberately setting weak power you can make it score lines rather than cut and by changing the z offset of the laser you can cause it to become unfocused, creating thicker lines. I used these ideas to create 3 lines of different thickness and darkness for both acrylic and wood scoring. The super fine lines were used in detail, like my leaves, whilst the thicker lines were used for the parametric scores and other embellishing.

Drawings

The laser cutter can engrave grey-scale images by modulating the power of the laser to the darkness of the pixel. So black engraves deeply and white is not touched. This works well for engraving photos of drawings, however some of the contrast is lost because increasing the power of the laser can just deepen the cut rather than darkening the wood. The pieces here were drawn by some of my more artistic friends.

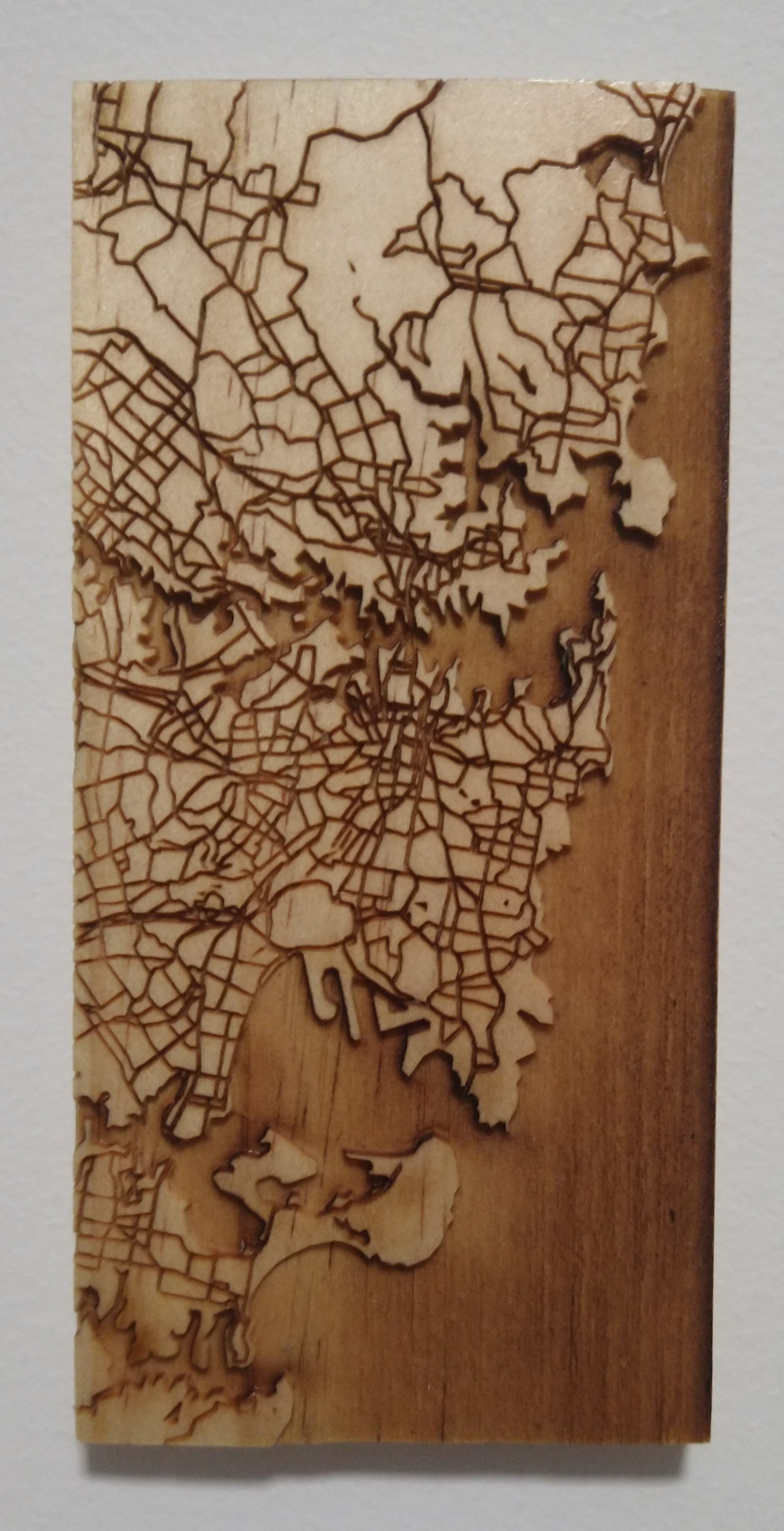

Maps

Maps are super easy to make because using the same method as engraving drawings. I used an online map creator to get the black and white images, them simply sent them to the laser. These maps are of Perth and Sydney, where I grew up and live.

Kinetic art

Laser cutting can also be used for more engineering work because it create any 2D part. This is a moving art piece I created because I was board. The crank down the bottom is connected by two oppositely strung rubber band transmission belts to the two turing disks on top. This makes the spiky parts rotate opposite directions and creates and interesting optical effect.

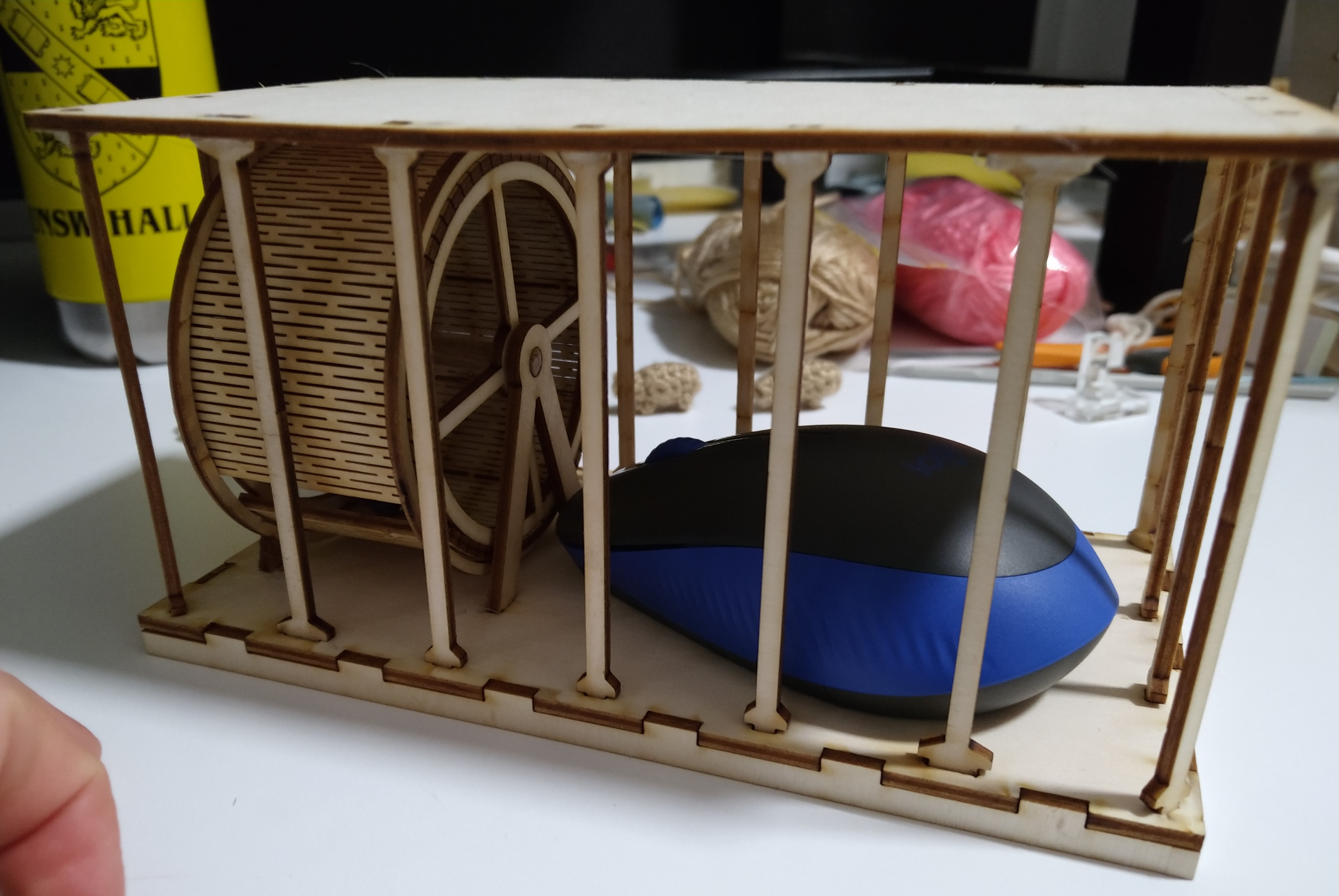

Mouse cage

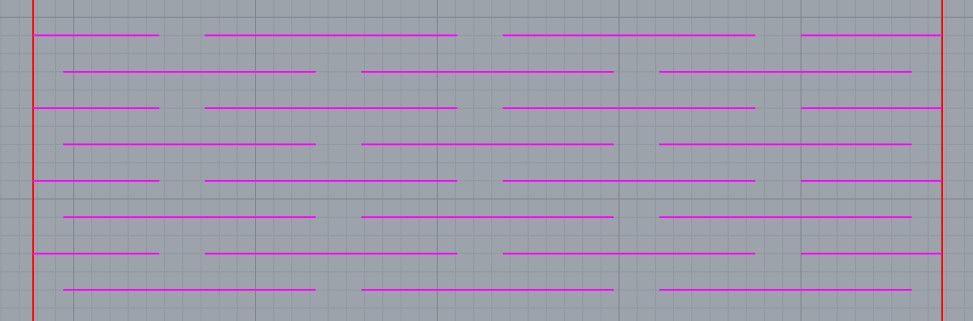

My university hall was going through a prank war so I decided to join in my own special way by creating a mouse cage puzzle for a computer mouse. I designed all the parts in 2D, cut them out and assembled them with hot glue. The cage is in two parts: the top with the bars fits onto the bottom, and the bottom has 4 friction fit pins that hold the top in place. The locking pins are hidden by a skirt so the bottom appears solid. I added a little working mouse wheel, which was interesting to make because it is not a flat 2D part. I used a wood bending technique where lots of lines are cut into thin wood as shown.

Friction fit

In several of my projects I use laser cut friction fits to join pieces or hold parts to bearings and axles. At first this took a lot of trial and error because I didn’t know the kerf (width of the cut) of the laser. After a while though the process got much easier because I had a better intuition of what the kerf would be in different materials. Wood is about 0.1mm and acrylic is around 0.08mm, however the exact kerf will depend on the laser settings, material type (even acrylic color affects it), and thickness.